Since plumbing was first created, the material utilized for funneling has been a significant component. At the beginning of plumbing in the old world, lead and mud funneling were utilized to move water to homes and public structures. In the mid-20th hundred years, while plumbing started to move into homes in the U.S., materials like cast iron, earthenware, copper, and electrifies steel were utilized. Lead funneling was additionally normal and was the material of decision for plumbing pipes until World War II.

Notwithstanding, as the comprehension of lead harming expanded, the prevalence of lead channeling tumbled off, especially for water that was intended to be consumable. After World War II, stirred screw channeling acquired favor as the material of decision for plumbing pipes inside the home, and years and years after the fact, during the 1970s, copper turned out to be more well known.

Most Common Types Of Plumbing Pipes

1. Copper Pipes

Handyman chipping away at pipes with text about copper pipes

Copper is one of the most conventional materials for plumbing lines and stays a famous choice today. There are two principal kinds of copper pipes that can be utilized together to furnish an entire pipes framework:

Inflexible Copper: Rigid, or hard, copper is involved all through a house or working for the water supply. The material can be cut into pieces and afterward welded together.

Adaptable Copper Tubing: Flexible, or delicate, copper is pliable and is utilized in short runs where space is tight and adaptability is required, for example, in corners or a stockpile line to your spigot.

Upsides and downsides of Copper Pipes

Copper pipes have gone the distance in light of a few significant benefits they have, including:

Life span: Copper is a solid material that can endure something like 50 years.

Sturdiness: Copper is a solid material that isn’t inclined to spillage or consumption.

Wellbeing: Bacteria can’t flourish in copper lines, and copper won’t dirty water in any capacity, so moving drinking water is protected.

Recyclability: When copper pipes ultimately should be supplanted, the material can be reused.

Temperature Tolerance: Copper can bear upping to outrageous temperature changes, including hot and cold water.

With such countless qualities, you might ask why copper isn’t utilized for plumbing for each situation.

2. Electrifies Steel Pipes

Electrified channeling used to be the material of decision for private pipes, and it is still what many individuals picture when they consider a pipes pipe. The steel pipes are covered in a layer of zinc, which is intended to forestall rusting.

These lines are without a doubt solid, however, they are not generally utilized much by any means. Excited pipes are still in some cases used to move non-consumable water, however, it is excessively inclined to issues to securely ship consumable water. While homes today are seldom equipped with stirred steel pipes, homes whose plumbing was introduced during the 1980s or before may in any case have them. If so in your home, you ought to think about supplanting these lines immediately.

3. Cons of Galvanized Steel Pipes

However electrifies steel pipes are less expensive than copper, and major areas of strength are figured out how to oppose rust for a period, these geniuses are far offset by the cons, which include:

Short Lifespan: Galvanized steel pipes last around 20 to 50 years before they start to separate. This life expectancy may not appear to be excessively short, yet it could not hope to compare to the life expectancies of numerous other funneling materials.

Rust: Especially in pipes with a little width, rust can develop inside over the long haul. At times, the rust can loosen up from within the walls of the line and wind up blending in with the water as it courses through. This stains the water.

Obstructs: Over time, mineral development within stirred lines can start to frame stops up that block the water stream.

Weakness: When excited pipes are harmed, the galvanization outwardly is compromised, which makes the line defenseless against consumption in a short measure of time

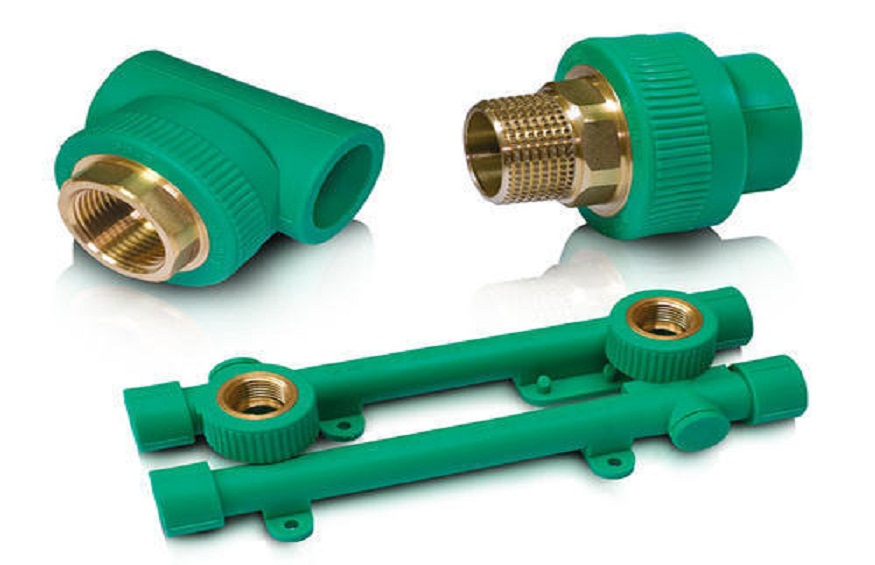

4. PPR Pipes

PPR-C pipes have turned into a famous decision for plumbing pipes lately. This material is a thermoplastic polymer. As such, it is made from a blend of plastic and vinyl. PPR pipes are unbending and are normally white, cream, or dark in variety. They are utilized most frequently for profoundly compressed water, for example, in a home’s principal water supply line.

Upsides and downsides of Polyvinyl Chloride Pipes

PPR pipes have acquired fame as a result of a few significant benefits they offer, including:

Life span: PPR isn’t likely to rust or erosion, so except if it encounters some kind of unforeseen harm, it can endure endlessly. Indeed, even the most strong metals utilized in plumbing pipes can’t satisfy the amazing life expectancy of PPR.

Capacity to Handle Pressure: PPR is frequently utilized for the fundamental inventory line that goes into your home since it can deal with high water pressure.

Convenience: PPR is very light contrasted with metal lines, which makes it simple to ship and work with. It is likewise simple to work with because there is no patching expected to associate lines. All things considered, pipes are stuck together.

Minimal expense: PPR is low in cost too. Particularly contrasted with copper, PPR is an extremely cheap choice for plumbing pipes.

While PPR enjoys a few stamped benefits, it has several burdens, as well.

Weakness to Warping: PPR isn’t prepared to move boiling water. This is because, as with most plastics, intensity can make the material twist and soften.

Size: Sizing choices for PPR pipes are restricted, which can be an issue now and again. Regardless of whether your PPR channeling is the ideal size, fittings used to associate PPR lines can generally be massive, which can be tricky in restricted spaces.