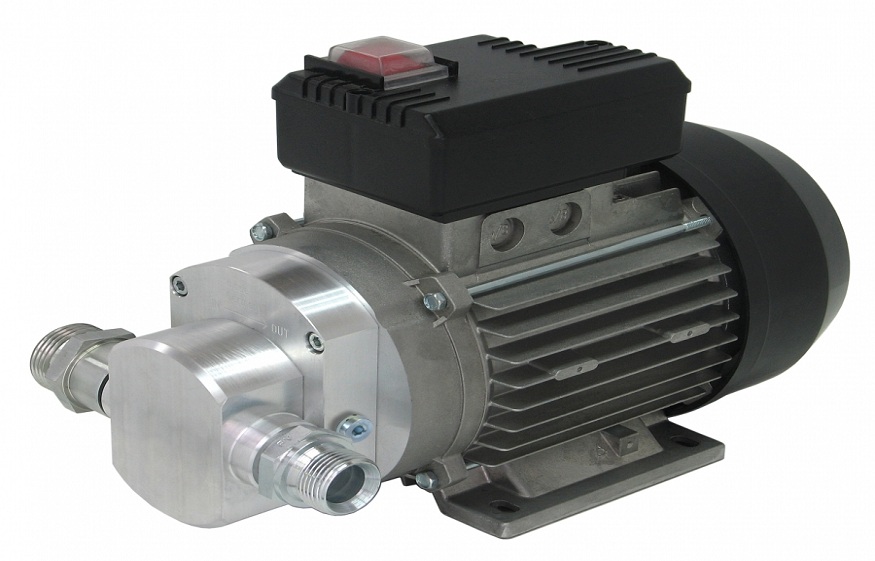

Installing pumping equipment may appear straightforward but small mistakes during setup can lead to major operational problems later. This is especially true when working with oil transfer systems where pressure flow and lubrication must remain stable at all times. An oil gear pump is widely used in industrial environments because of its reliable performance and precise flow control. However even the best pump design can fail to deliver expected results if it is installed incorrectly.

This article explores the most common installation mistakes to avoid with oil gear pumps. By understanding these issues and learning how to prevent them operators engineers and maintenance teams can improve efficiency reduce downtime and extend equipment life. Whether the application involves lubrication systems hydraulic circuits or industrial oil transfer the principles discussed here apply to any gear pump for oil handling.

Why Proper Installation Matters for Oil Gear Pumps

Oil gear pumps operate as positive displacement systems. This means they move a fixed amount of fluid with each rotation. While this design ensures consistent flow it also makes the pump sensitive to installation conditions.

Incorrect alignment poor piping design or inadequate lubrication can increase wear cause noise and reduce performance. In severe cases improper installation may result in seal failure gear damage or complete pump breakdown. Paying attention to installation details protects both the pump and the overall system.

Mistake One Incorrect Pump Alignment

One of the most common and damaging mistakes is improper alignment between the pump and the drive source. Misalignment creates uneven loading on bearings and gears which accelerates wear.

An oil gear pump must be aligned accurately with the motor or engine shaft. Even small angular or parallel misalignments can cause vibration heat buildup and premature failure. Using proper alignment tools and checking alignment after initial startup are essential steps that should never be skipped.

Mistake Two Ignoring Shaft and Coupling Considerations

Closely related to alignment is the choice and installation of couplings. Flexible couplings are often used to accommodate minor misalignment but they are not a substitute for correct alignment.

Installing the wrong coupling type or tightening it incorrectly can place additional stress on the pump shaft. This can lead to seal leakage or shaft damage. Always ensure that the coupling is rated for the required torque and installed according to manufacturer guidelines.

Mistake Three Poor Suction Line Design

The suction side of an oil gear pump plays a critical role in performance. Poor suction piping design is a frequent installation error that leads to cavitation noise and reduced flow.

Common issues include undersized suction lines excessive bends and long pipe runs. These conditions restrict oil flow and cause pressure drop at the pump inlet. A gear pump for oil should always have a short straight and adequately sized suction line to ensure smooth fluid entry.

Mistake Four Failing to Prime the Pump

Another common oversight is failing to prime the pump before startup. Gear pumps rely on oil to lubricate internal components and create a seal between the gears and housing.

Starting an oil gear pump without oil inside can cause immediate damage due to dry running. Always ensure the pump is fully primed and filled with oil before initial operation. In some systems this may require manual filling or venting trapped air from the pump casing.

Mistake Five Incorrect Rotation Direction

Gear pumps are designed to operate in a specific rotation direction unless they are built for bidirectional use. Installing the pump without verifying rotation can result in no flow or reversed flow.

Before startup confirm that the motor rotation matches the pump design. Incorrect rotation may also damage seals and reduce lubrication effectiveness. This simple check can prevent costly repairs and system downtime.

Mistake Six Overlooking Pressure Relief Protection

Because an oil gear pump is a positive displacement device it will continue to build pressure if the discharge line is blocked. Without proper pressure relief this can cause catastrophic failure.

A common installation mistake is neglecting to include a pressure relief valve or installing one incorrectly. Relief devices must be properly sized and set to protect both the pump and downstream components. Never rely on the pump itself to manage excess pressure.

Mistake Seven Using Improper Mounting Techniques

The way a pump is mounted affects vibration noise and alignment stability. Mounting the pump on an uneven or flexible surface can cause movement during operation.

An oil gear pump should be installed on a rigid level base that can support its weight and operating forces. Bolts should be tightened evenly and mounting surfaces should be checked for flatness. Proper mounting ensures long term stability and consistent performance.

Mistake Eight Neglecting Temperature and Viscosity Factors

Oil properties change with temperature and this can affect pump performance. Installing a gear pump for oil without considering operating temperature can lead to problems.

Cold oil may be too viscous for the pump to handle at startup causing high torque and stress. Hot oil may reduce lubrication effectiveness and increase leakage. Installation planning should account for temperature ranges and include heating or cooling measures if necessary.

Mistake Nine Inadequate Filtration and Cleanliness

Oil contamination is a leading cause of gear pump wear. Installing a pump without proper filtration exposes gears and bearings to abrasive particles.

A common mistake is placing filters only on the discharge side or using filters with incorrect ratings. Proper filtration on the suction side helps protect the pump from damage. Clean installation practices including flushing pipes before connection also play a vital role in maintaining oil quality.

Mistake Ten Improper Seal Handling During Installation

Seals are critical components that prevent oil leakage and maintain pressure. Mishandling seals during installation can cause leaks from the very first startup.

Using sharp tools incorrect lubricants or excessive force can damage seal surfaces. Always handle seals carefully and use compatible lubricants during assembly. Proper seal installation supports long term leak free operation.

Mistake Eleven Skipping Initial Performance Checks

After installation many operators rush the startup process without thorough testing. This can hide early warning signs of installation issues.

Initial checks should include monitoring pressure flow temperature and noise levels. Observing the oil gear pump during its first hours of operation helps identify alignment issues air entrainment or abnormal vibration. Addressing these signs early prevents larger failures later.

Mistake Twelve Lack of Documentation and Training

Even a perfectly installed pump can suffer if operators are not trained on proper use. Failing to document installation details settings and maintenance requirements is a common oversight.

Clear documentation helps future technicians understand system design and operating limits. Training ensures that daily operation does not introduce avoidable stress on the gear pump for oil applications.

Best Practices to Ensure Successful Installation

Avoiding installation mistakes begins with careful planning. Reviewing system requirements selecting proper components and following installation guidelines are key steps.

Working with experienced technicians and allowing adequate time for setup improves results. Using checklists during installation helps ensure that no critical step is missed. A well installed oil gear pump delivers consistent performance and long service life.

Oil gear pumps are reliable and efficient when installed correctly but they are sensitive to installation quality. Common mistakes such as poor alignment inadequate suction design lack of priming and missing pressure protection can significantly reduce pump life.

By understanding these pitfalls and following best practices, operators can ensure that a gear pump for oil performs as intended. Proper installation not only protects the pump but also improves system efficiency safety and long term operating value. Investing time and attention during installation pays dividends throughout the life of the equipment.